Belt Sander Deburring / Finishing Help

-

38aRacer

- 1/2 Star Member

- Posts: 1

- Joined: Sun Jan 05, 2020 9:58 am

Belt Sander Deburring / Finishing Help

What is the best bang for your buck Conveyor Belt Sander 36" wide approximately? Not looking to break the bank but looking for a solid machine.Thanks

-

cuttinparts

- 3 Star Member

- Posts: 357

- Joined: Tue Sep 30, 2008 3:40 pm

Re: Belt Sander Deburring / Finishing Help

What are trying to do with it? I had an affordable one years ago for putting a brushed finish in aluminum but it wouldn't be tough enough for anyone trying to take slag off or anything like that.

-

ccoatings

- 1 Star Member

- Posts: 13

- Joined: Tue May 12, 2020 10:29 pm

Re: Belt Sander Deburring / Finishing Help

I am looking at the Laguna Tools 36" Wide Belt Metal Sander, the compact series.

- cstroke

- 3 Star Elite Contributing Member

- Posts: 405

- Joined: Thu May 24, 2012 7:45 pm

Re: Belt Sander Deburring / Finishing Help

It says minimum height is 1/8" thick?

6’x12’ Dynatorch powermax 85

12’ Wysong brake

5’x 5/16’ wysong rolls

3.8’x10’ shear

65 Ton ironworker

Boss laser 3655 150 watt CO2.

SFX 100watt Mopa

Quicncy 7.5hp

Square wave tig, Multimatics, Miller bobcat efi.

12’ Wysong brake

5’x 5/16’ wysong rolls

3.8’x10’ shear

65 Ton ironworker

Boss laser 3655 150 watt CO2.

SFX 100watt Mopa

Quicncy 7.5hp

Square wave tig, Multimatics, Miller bobcat efi.

- cstroke

- 3 Star Elite Contributing Member

- Posts: 405

- Joined: Thu May 24, 2012 7:45 pm

Re: Belt Sander Deburring / Finishing Help

Anyone used these with success?? 12k is a bunch of cash if it doesnt remove dross..

6’x12’ Dynatorch powermax 85

12’ Wysong brake

5’x 5/16’ wysong rolls

3.8’x10’ shear

65 Ton ironworker

Boss laser 3655 150 watt CO2.

SFX 100watt Mopa

Quicncy 7.5hp

Square wave tig, Multimatics, Miller bobcat efi.

12’ Wysong brake

5’x 5/16’ wysong rolls

3.8’x10’ shear

65 Ton ironworker

Boss laser 3655 150 watt CO2.

SFX 100watt Mopa

Quicncy 7.5hp

Square wave tig, Multimatics, Miller bobcat efi.

-

adbuch

- 6 Star Elite Contributing Member

- Posts: 8658

- Joined: Thu Sep 21, 2017 5:22 pm

- Location: Tucson, Arizona

- Contact:

Re: Belt Sander Deburring / Finishing Help

And if the minimum material thickness is 1/8" this would leave out many of the folks doing artistic projects from thinner material.

David

David

-

ccoatings

- 1 Star Member

- Posts: 13

- Joined: Tue May 12, 2020 10:29 pm

Re: Belt Sander Deburring / Finishing Help

I did end up getting it, and it removes and finishes the pieces very well. The minimum listed is wrong, I run 16G continuously, and it works great, I also run my stainless bottle openers through it that are 8 inches long, so no issues there. I did discover that the different belt manufacturers do have some differences in their belts. I like combat abrasives the best so far. Either zirconium, or the ceramic. I'm on deployment right now, otherwise I would have some photos. I've been using it for straight line graining as well.

-

adbuch

- 6 Star Elite Contributing Member

- Posts: 8658

- Joined: Thu Sep 21, 2017 5:22 pm

- Location: Tucson, Arizona

- Contact:

Re: Belt Sander Deburring / Finishing Help

Thanks for the update! It sounds like it works great.

David

David

- cstroke

- 3 Star Elite Contributing Member

- Posts: 405

- Joined: Thu May 24, 2012 7:45 pm

Re: Belt Sander Deburring / Finishing Help

I'm really considering one of these. Do you have to do any hand grinding or will this machine get rid of all of it?

Low speed dross in 18ga material?

How does it do with intricate stuff with catching items?

I've been told the oscillation really helps.

Any thoughts?

I've been doing the acid bath then grind, then sandblast and to the powdercoater.

I'd think this should be a run through maybe a few times and send to the powdercoater.

Difficult to spend that much money without knowing all the details.

Any help would be appreciated.

Thanks

Chris

Low speed dross in 18ga material?

How does it do with intricate stuff with catching items?

I've been told the oscillation really helps.

Any thoughts?

I've been doing the acid bath then grind, then sandblast and to the powdercoater.

I'd think this should be a run through maybe a few times and send to the powdercoater.

Difficult to spend that much money without knowing all the details.

Any help would be appreciated.

Thanks

Chris

6’x12’ Dynatorch powermax 85

12’ Wysong brake

5’x 5/16’ wysong rolls

3.8’x10’ shear

65 Ton ironworker

Boss laser 3655 150 watt CO2.

SFX 100watt Mopa

Quicncy 7.5hp

Square wave tig, Multimatics, Miller bobcat efi.

12’ Wysong brake

5’x 5/16’ wysong rolls

3.8’x10’ shear

65 Ton ironworker

Boss laser 3655 150 watt CO2.

SFX 100watt Mopa

Quicncy 7.5hp

Square wave tig, Multimatics, Miller bobcat efi.

-

dannymcclure67

- 1 Star Member

- Posts: 16

- Joined: Fri Dec 27, 2019 9:53 pm

Re: Belt Sander Deburring / Finishing Help

Can the timesaver machines be used on metal if it was originally meant for wood?

-

adbuch

- 6 Star Elite Contributing Member

- Posts: 8658

- Joined: Thu Sep 21, 2017 5:22 pm

- Location: Tucson, Arizona

- Contact:

Re: Belt Sander Deburring / Finishing Help

Probably not very successfully. It looks to me like Timesavers makes specific machines for wooddannymcclure67 wrote: ↑Sat Jul 03, 2021 9:44 pm Can the timesaver machines be used on metal if it was originally meant for wood?

https://timesaversinc.com/wood-solutions

and specific machines for metal.

https://timesaversinc.com/metal-solutions

There has been some discussion on converting wide belt sanders originally intended for wood to use for metal here.

David

https://www.practicalmachinist.com/vb/w ... al-357952/

-

Dishtech55

- 2 Star Member

- Posts: 95

- Joined: Tue Oct 02, 2018 9:21 pm

- Location: Central Illinois

- Contact:

Re: Belt Sander Deburring / Finishing Help

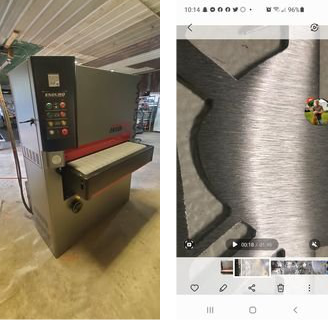

I ordered the Laguna MW37C, Wide Belt Sander also. should be here in a few weeks. Cant wait. A lot of my Cuts are 36x36, and last Christmas., All the orders came in at last minute.. I didn't think I would ever get all of them sanded by Hand, with out my hand falling off...lol but I did.. So this is like an extra person helping me. They are ready for my Powder Coating oven. I can now cut , Sand , and powder and out the door less than an hour on each piece. I picked the Laguna because of the Price. EZ sander is several Thousands Higher. Plus I bought mine at USToolsDepot. They are $1000.00 cheaper on the same machine as others , plus NO Sales Taxes.. That's another $1000.00 savings...I have an industrial 36" dual drum Sander, That im going to sell on here, if anyone is interested in it. Only had it for a bout a month, used it several times and it quit. only to later after ordering New Laguna wide belt sander, it was my main breaker on my electric box was bad.. only had one side.. replaced the box,, and bam.. its up and sanding .. So it going to be for sale..$5500.00 and it is for Metal... I was told Metal Drums turn opposite way as wood.

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

4x10 Home Built Super Table.

4x4x6` Home Built LP Powder Coat oven

Hypertherm 45 xp plasma cutter

Eastwood 60 amp Plasma Cutter

Eastwood Powder Coating Gun

Miller 252 Mig with Spool Gun

Lincoln 100 Mig

Build Trailers

4x4x6` Home Built LP Powder Coat oven

Hypertherm 45 xp plasma cutter

Eastwood 60 amp Plasma Cutter

Eastwood Powder Coating Gun

Miller 252 Mig with Spool Gun

Lincoln 100 Mig

Build Trailers

-

ccoatings

- 1 Star Member

- Posts: 13

- Joined: Tue May 12, 2020 10:29 pm

Re: Belt Sander Deburring / Finishing Help

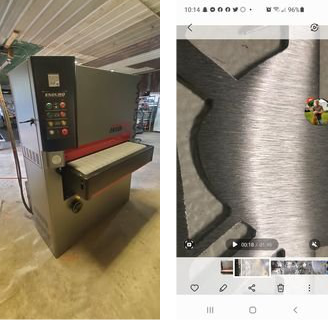

I usually run the back side in a few passes (changing orientation) to deburr or get any heavy dross spots, then the front on one or two depending on the finish I want. If it is brushed, then one pass in the direction I want the strokes. I have not hand grinded since purchasing this. I can then take straight to powder from there. It really does great. I do like the combat abrasives belts the best for it. I am still messing with what grit and type I like best, but those will vary amongst end result. The drum is soft, so you will get some edge rounding depending on your settings which is great for the powder to prevent edge pull. I tried empire, but they wore down fairly quick over Combat. The zirconium does last a good while. I am going to try the ceramic next. I really am hay with the purchase, I ran a tone of art through it the last few weeks and it keeps ticking. I opted to forgo their dust collector, I plan on making my own with a poly drum with water, like their cut sheet shows.

I'll have to get some photos, but I have sent some intricate arts through, just be aware of orientation - some may ass through better in certain angles to keep things from getting caught.

I'll have to get some photos, but I have sent some intricate arts through, just be aware of orientation - some may ass through better in certain angles to keep things from getting caught.

-

Dishtech55

- 2 Star Member

- Posts: 95

- Joined: Tue Oct 02, 2018 9:21 pm

- Location: Central Illinois

- Contact:

Re: Belt Sander Deburring / Finishing Help

THIS ITEM IS SOLD.. THANKS FOR ALL WHO ASKED ABOUT IT..Dishtech55 wrote: ↑Mon Aug 16, 2021 10:34 am I ordered the Laguna MW37C, Wide Belt Sander also. should be here in a few weeks. Cant wait. A lot of my Cuts are 36x36, and last Christmas., All the orders came in at last minute.. I didn't think I would ever get all of them sanded by Hand, with out my hand falling off...lol but I did.. So this is like an extra person helping me. They are ready for my Powder Coating oven. I can now cut , Sand , and powder and out the door less than an hour on each piece. I picked the Laguna because of the Price. EZ sander is several Thousands Higher. Plus I bought mine at USToolsDepot. They are $1000.00 cheaper on the same machine as others , plus NO Sales Taxes.. That's another $1000.00 savings...I have an industrial 36" dual drum Sander, That im going to sell on here, if anyone is interested in it. Only had it for a bout a month, used it several times and it quit. only to later after ordering New Laguna wide belt sander, it was my main breaker on my electric box was bad.. only had one side.. replaced the box,, and bam.. its up and sanding .. So it going to be for sale..$5500.00 and it is for Metal... I was told Metal Drums turn opposite way as wood.

229847377_183251473735750_1838594234996692402_n.jpg

4x10 Home Built Super Table.

4x4x6` Home Built LP Powder Coat oven

Hypertherm 45 xp plasma cutter

Eastwood 60 amp Plasma Cutter

Eastwood Powder Coating Gun

Miller 252 Mig with Spool Gun

Lincoln 100 Mig

Build Trailers

4x4x6` Home Built LP Powder Coat oven

Hypertherm 45 xp plasma cutter

Eastwood 60 amp Plasma Cutter

Eastwood Powder Coating Gun

Miller 252 Mig with Spool Gun

Lincoln 100 Mig

Build Trailers

-

Dishtech55

- 2 Star Member

- Posts: 95

- Joined: Tue Oct 02, 2018 9:21 pm

- Location: Central Illinois

- Contact:

Re: Belt Sander Deburring / Finishing Help

I got my new Laguna 37" Wide belt sander a couple weeks ago! I love this thing! It will take off the dross in a couple passes or so. I dont force too much of a bit. I rather run through a few times., I also just started taking my items off the table and hitting the dross with a wire wheel on my side Grinder real fast to take most of it off.. It saves the belts, and it only takes about 5 seconds. I use 80 grit Zirconium sanding Belt to get the dross, and 100 grit for a perfect shinny surface. I cant beleive the time I save in my shop. and its fun to use.. I hooked up a dust collector to it also. Best thing to have in the shop beside the table. It takes the scale off of hot roll. and shines it up nice. I like it because. when I get ready to use it, on 16 gauge, I stick a small piece of 16 gauge in between to touch points on the machine, and push button down on the table. and it will sandwich the metal and stop where it need to be . and its ready for 16 gauge. no guessing . $12999.00 plus $399.00 shipping. ordered in Aug and got 13th of this month (Oct). 37x60" paper. average around $50 a sheet. but seem to last pretty good.

4x10 Home Built Super Table.

4x4x6` Home Built LP Powder Coat oven

Hypertherm 45 xp plasma cutter

Eastwood 60 amp Plasma Cutter

Eastwood Powder Coating Gun

Miller 252 Mig with Spool Gun

Lincoln 100 Mig

Build Trailers

4x4x6` Home Built LP Powder Coat oven

Hypertherm 45 xp plasma cutter

Eastwood 60 amp Plasma Cutter

Eastwood Powder Coating Gun

Miller 252 Mig with Spool Gun

Lincoln 100 Mig

Build Trailers

-

DieselFumes

- 3.5 Star Member

- Posts: 538

- Joined: Thu Dec 05, 2019 11:33 am

Re: Belt Sander Deburring / Finishing Help

Dishtech55, that's is awesome! Glad to hear its working so well for you, a little on the costly side for many but for anyone cranking out a lot of parts this would be a huge time saver. I assumed the dross would rip the belts to pieces. Great looking machine too!

-

ccoatings

- 1 Star Member

- Posts: 13

- Joined: Tue May 12, 2020 10:29 pm

Re: Belt Sander Deburring / Finishing Help

Which Dust collector are you running? I haven't put one on mine yet, really would like to have one. I thought about doing a wet system with a poly drum.Dishtech55 wrote: ↑Thu Oct 28, 2021 11:35 am I got my new Laguna 37" Wide belt sander a couple weeks ago! I love this thing! It will take off the dross in a couple passes or so. I dont force too much of a bit. I rather run through a few times., I also just started taking my items off the table and hitting the dross with a wire wheel on my side Grinder real fast to take most of it off.. It saves the belts, and it only takes about 5 seconds. I use 80 grit Zirconium sanding Belt to get the dross, and 100 grit for a perfect shinny surface. I cant beleive the time I save in my shop. and its fun to use.. I hooked up a dust collector to it also. Best thing to have in the shop beside the table. It takes the scale off of hot roll. and shines it up nice. I like it because. when I get ready to use it, on 16 gauge, I stick a small piece of 16 gauge in between to touch points on the machine, and push button down on the table. and it will sandwich the metal and stop where it need to be . and its ready for 16 gauge. no guessing . $12999.00 plus $399.00 shipping. ordered in Aug and got 13th of this month (Oct). 37x60" paper. average around $50 a sheet. but seem to last pretty good.

-

Dishtech55

- 2 Star Member

- Posts: 95

- Joined: Tue Oct 02, 2018 9:21 pm

- Location: Central Illinois

- Contact:

Re: Belt Sander Deburring / Finishing Help

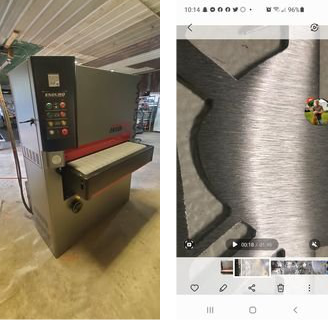

I boght a Harbor Freight one. the 2 hp bigger one. it does have plastic bag on bottom. but replaced it with cloth one same as top.But this winter, going to put a metal barrel on bottom. I was told these can sometime catch fire if cloth. But seen several videos on youtube with replacing with barrel.

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

4x10 Home Built Super Table.

4x4x6` Home Built LP Powder Coat oven

Hypertherm 45 xp plasma cutter

Eastwood 60 amp Plasma Cutter

Eastwood Powder Coating Gun

Miller 252 Mig with Spool Gun

Lincoln 100 Mig

Build Trailers

4x4x6` Home Built LP Powder Coat oven

Hypertherm 45 xp plasma cutter

Eastwood 60 amp Plasma Cutter

Eastwood Powder Coating Gun

Miller 252 Mig with Spool Gun

Lincoln 100 Mig

Build Trailers

-

adbuch

- 6 Star Elite Contributing Member

- Posts: 8658

- Joined: Thu Sep 21, 2017 5:22 pm

- Location: Tucson, Arizona

- Contact:

Re: Belt Sander Deburring / Finishing Help

That's a nice unit! I have the same one and use it for my cnc wood router. But I went a different route for my plasma table.Dishtech55 wrote: ↑Thu Dec 16, 2021 12:23 pm I boght a Harbor Freight one. the 2 hp bigger one. it does have plastic bag on bottom. but replaced it with cloth one same as top.But this winter, going to put a metal barrel on bottom. I was told these can sometime catch fire if cloth. But seen several videos on youtube with replacing with barrel.

David

-

Dishtech55

- 2 Star Member

- Posts: 95

- Joined: Tue Oct 02, 2018 9:21 pm

- Location: Central Illinois

- Contact:

Re: Belt Sander Deburring / Finishing Help

UP DATE ON LAGUNA 37" table. I'm very happy with the Laguna sander.. Not many instructions. and had to learn it. But works Great. Very easy to setup for what gauge still you are running through it.. you just put a piece of any gauge in between the auto gauge setting item and push button up for the table to go up, and when it gets right, It will stop.. and your all set for that gauge of metal. now I have a manual crank that I also adjust so when metal goes through it , I have to watch the Amp gauge, and adjust to around 35 -40 amps.. anything more, it will kick out the motor. Its a safety item to save from burning out the motor. When I pull metal off my plasma table.. I do run a knotted Wire Brush over it real quit to knock off the worst dross. This saves my sand Paper usage a lot.. It will take off the dross, no problem but it also take life from your sand paper. and its like $55.00 average for good sand paper, I use 60 0r 80 grit first, then switch out to 100 grit. comes out nice. I have went as small as 18 Gauge steel in it.

4x10 Home Built Super Table.

4x4x6` Home Built LP Powder Coat oven

Hypertherm 45 xp plasma cutter

Eastwood 60 amp Plasma Cutter

Eastwood Powder Coating Gun

Miller 252 Mig with Spool Gun

Lincoln 100 Mig

Build Trailers

4x4x6` Home Built LP Powder Coat oven

Hypertherm 45 xp plasma cutter

Eastwood 60 amp Plasma Cutter

Eastwood Powder Coating Gun

Miller 252 Mig with Spool Gun

Lincoln 100 Mig

Build Trailers