Good day people

i have built a small (1mx1m) CNC Plasma table using stepper motors with LPT port Card running Mach3 full license. the Plasma source is a Herocut 55 Non-HF machine with a straight machine torch PTM80. every thing is setup and runs well with straight and thick material.

i have a problem with thin or warped material. Ok no problem need a THC. so i got POLABS PlasmaSensOut wired all up and its works ok. now i need to connect a ohmic / Probe, the problem i have is with the plasma source switch on there is permanent continuity from my torch tip to my earth clamp( even if its not attached or touching the table. but with the plasma source switch off there is no continuity from torch to tip and probe works to fine to detect the surface. any ideas on how to combat this problem. i cant be switching the source off every time the machine needs to start a cut.

Ohmic/Probe setup problem

- djreiswig

- 4.5 Star Elite Contributing Member

- Posts: 1939

- Joined: Thu Nov 19, 2015 10:02 pm

- Location: SE Nebraska

Re: Ohmic/Probe setup problem

Maybe you could add an insulated probe to the side of the torch. You would have to work out the offsets to get the torch to end up at the correct height.

2014 Bulltear (StarLab) 4x8

C&CNC EtherCut

Mach3, SheetCam, Draftsight

Hypertherm PM65

Oxy/Acetylene Flame Torch

Pneumatic Plate Marker, Ohmic, 10 inch Rotary Chuck (in progress)

C&CNC EtherCut

Mach3, SheetCam, Draftsight

Hypertherm PM65

Oxy/Acetylene Flame Torch

Pneumatic Plate Marker, Ohmic, 10 inch Rotary Chuck (in progress)

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 7796

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Ohmic/Probe setup problem

I looked up the site for the manual for the POLABS PlasmaSensOut this unit looks like a rebranding of the Proma THC and seems to function the same.

Now hooking up a THC and a Ohmic sensor are 2 separate units with no connections. The Ohmic sensor is only used to establish the position of the torch before the cutting operation starts. The THC only is active when you are actually cutting. This why djreswig is talking about an insulated tip for the torch, there should not be a electrical connection to plasma torch circuit. There will be a connection to the work metal as a return path for the ohmic sensor circuit and a insulated tip on the torch that does touch the metal surface for it to work. This circuit is also separate in Mach as a Z home or Probe input. The THC connections signals are for arc OK, torch up , and torch down, it only connects to the metal surface as a return for the arc voltage path for controlling the torch during the cutting operation.

Now hooking up a THC and a Ohmic sensor are 2 separate units with no connections. The Ohmic sensor is only used to establish the position of the torch before the cutting operation starts. The THC only is active when you are actually cutting. This why djreswig is talking about an insulated tip for the torch, there should not be a electrical connection to plasma torch circuit. There will be a connection to the work metal as a return path for the ohmic sensor circuit and a insulated tip on the torch that does touch the metal surface for it to work. This circuit is also separate in Mach as a Z home or Probe input. The THC connections signals are for arc OK, torch up , and torch down, it only connects to the metal surface as a return for the arc voltage path for controlling the torch during the cutting operation.

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

Rodw

- 4 Star Member

- Posts: 780

- Joined: Sun Aug 21, 2016 1:49 am

- Location: Brisbane, Australia

- Contact:

Re: Ohmic/Probe setup problem

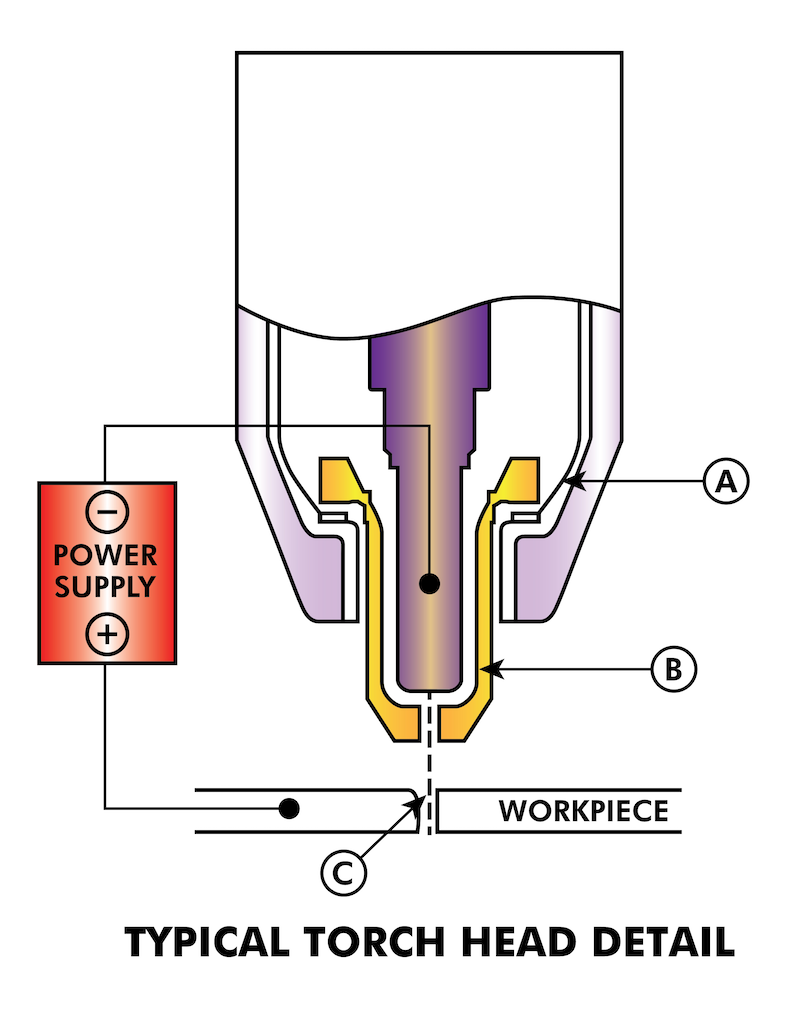

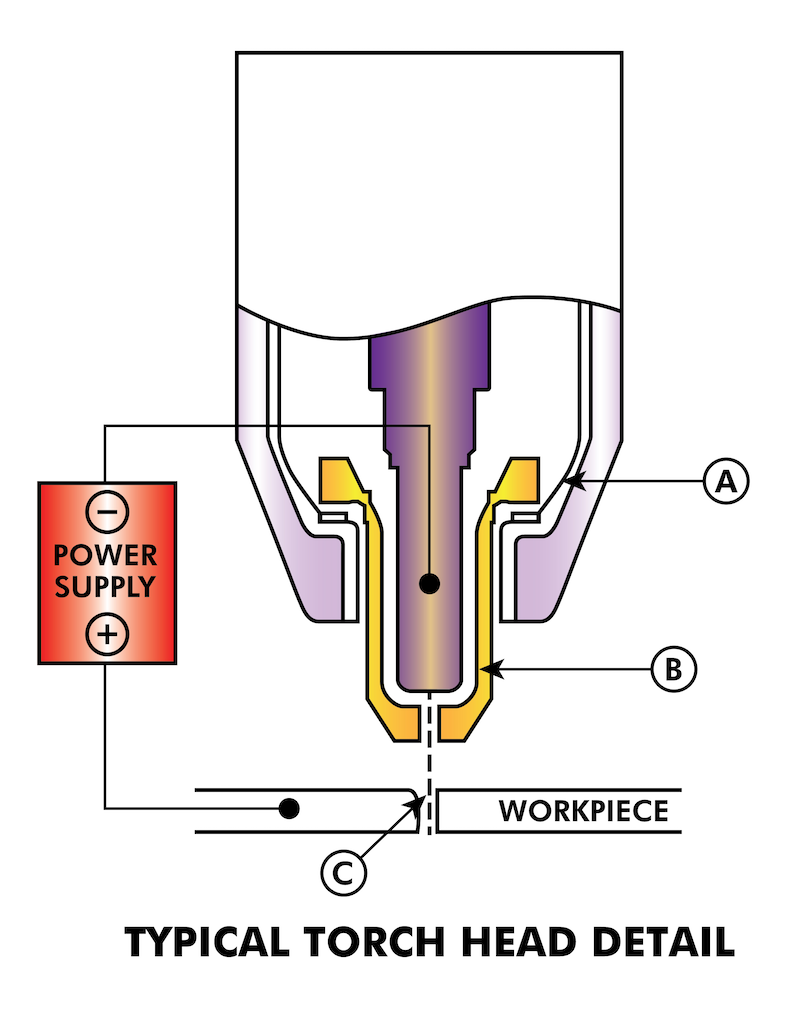

What has not been explained is that where ohmic sensing is used, the torch concerned (eg Thermal Dynamics and Hypertherm) has a torch shield that is isolated from the tip. The ohmic connection is between the material and the shield. So there is not a safe way to implement ohmic sensing in your situation. This diagrram shows what I mean. (The shield is in gold)

See: http://linuxcnc.org/docs/devel/html/pla ... rimer.html

You would be better off building a float switch. These work well on thicker material but its not ideal on thin material.

See: http://linuxcnc.org/docs/devel/html/pla ... rimer.html

You would be better off building a float switch. These work well on thicker material but its not ideal on thin material.

-

DutchPlasma

- 1/2 Star Member

- Posts: 4

- Joined: Sun Dec 15, 2019 1:53 pm

Re: Ohmic/Probe setup problem

Strange, I would have thought that the shield is always insulated from the electrode, if it wasn't wouldn't you create a short circuit when cutting?

Are you sure the torch is assembled correctly?

Both the supplied hand torch and the aftermarket Binzel Machine torch I fitted to my Chinese 70 Amp Plasma do not have the shield conducting electricity at all. The Binzel torch I have retrofitted with a Ohmic Probe (just drilled a small hole into the glassfibre spatter cap, and then used a small piece of wire to connect to the shield cap, to use as the torch input for my Ohmic sensor.

The old Chinese hand torch had the same setup fitted, and that also had the shield electrically isolated from the rest of the torch.

If your machine indeed has the shield connected to ground then there could also be a workaround:

If you have acces to a lathe could you not make a small disc from non conductive material, and fit it in your torch (if I take the above picture,as an

example a small disc fitted under the shield where the 2 small rectangular parts are drawn would probably seperate the shield electrically from the ground.

As a test a small o-ring could be used as well, then you can test the machine if it does work with the shield disconnected from ground, and then a small fibreglass or high temp plastic spacer ring could then be machines

Are you sure the torch is assembled correctly?

Both the supplied hand torch and the aftermarket Binzel Machine torch I fitted to my Chinese 70 Amp Plasma do not have the shield conducting electricity at all. The Binzel torch I have retrofitted with a Ohmic Probe (just drilled a small hole into the glassfibre spatter cap, and then used a small piece of wire to connect to the shield cap, to use as the torch input for my Ohmic sensor.

The old Chinese hand torch had the same setup fitted, and that also had the shield electrically isolated from the rest of the torch.

If your machine indeed has the shield connected to ground then there could also be a workaround:

If you have acces to a lathe could you not make a small disc from non conductive material, and fit it in your torch (if I take the above picture,as an

example a small disc fitted under the shield where the 2 small rectangular parts are drawn would probably seperate the shield electrically from the ground.

As a test a small o-ring could be used as well, then you can test the machine if it does work with the shield disconnected from ground, and then a small fibreglass or high temp plastic spacer ring could then be machines

-

Rodw

- 4 Star Member

- Posts: 780

- Joined: Sun Aug 21, 2016 1:49 am

- Location: Brisbane, Australia

- Contact:

Re: Ohmic/Probe setup problem

What you are missing is that a blowback torch has to create a short in the tip to create the arc before air pressure blows it apart so the arc transfers to the material. Every torch is different no doubt but many torches actually expose the tip which on higher end machines sit behind a shield. I did get as far as modifying my unshielded torch to try ohmic sensing before I woke up to this.DutchPlasma wrote: ↑Tue Dec 24, 2019 6:17 pm Strange, I would have thought that the shield is always insulated from the electrode, if it wasn't wouldn't you create a short circuit when cutting?

Without seeing the OP's torch and testing with a multimeter, everything is conjecture.

There is a solution (I think) but its only possible with Linuxcnc and its what I use on my machine. That is to do what I call Hypersensing using a Mesa THCAD-5 And an isolated power supply that is isolated to 500 volts. The THCAD-5 can handle 500 volts overvoltage indefinitely so that means the ohmic sensing circuit becomes impervious to torch voltage and can be safely left connected and powered up all the time. The logic sensing signals on the THCAD are 100% isolated from the torch voltage so this is safe..

-

DutchPlasma

- 1/2 Star Member

- Posts: 4

- Joined: Sun Dec 15, 2019 1:53 pm

Re: Ohmic/Probe setup problem

Indeed, both my torches are HF, so you are probably very right about this issue on blowback torches.

As far as shielding torch voltage I believe the Robot3T Ohmic unit does exactly the same, IE isolate plasma power from the rest of the system.

If the shield is indeed conductive, and the isolating ring trick can not be used, then I would maybe make a small probing pin, which is clamped onto the torch body, from a small metal rod, that is bent so that it sits a few mm from the actual shield, and is the same hight, that way the ohmic sensor can use the probe tip, instead of the shield?

As far as shielding torch voltage I believe the Robot3T Ohmic unit does exactly the same, IE isolate plasma power from the rest of the system.

If the shield is indeed conductive, and the isolating ring trick can not be used, then I would maybe make a small probing pin, which is clamped onto the torch body, from a small metal rod, that is bent so that it sits a few mm from the actual shield, and is the same hight, that way the ohmic sensor can use the probe tip, instead of the shield?

-

wes709

- 1/2 Star Member

- Posts: 2

- Joined: Wed May 27, 2020 10:16 pm

Re: Ohmic/Probe setup problem

Hello , what was your outcome to this ? what did you do to get you hero cut 55i to work with ohmic sensing,

regards

wes

regards

wes