I take a 1/2" strip of 3/16" steel, about 45" long I think, and roll it into a ring, where it gets welded to the inner ring. This is an "anti-coning ring" and is not needed, but I put them on all my beadlocks. I roll them with a homemade ring roller. Pretty quick and easy peezy.

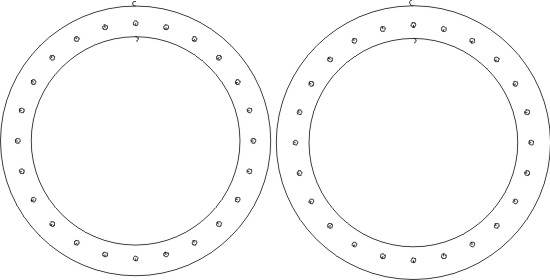

I also cut the 24 holes smaller than needed, then drill them out to 3/8" on my drill press. We all know how plasma CNC makes perfect holes right....

The inner ring is the one that is just a titch smaller (titch is a word, right...) that one gets welded to the steel wheel. No steel needs to be removed from the wheel, just the paint, chrome or powder coat where the welding will take place.

Set it in place and center it with your fingers.

Weld it in.

The larger one needs to have some grinding done to it. Grind the outer edge with a nice radius where it will contact the tire. You don't want this thing to cut the bead off... just pinch it.

Get some tire lube at your local fleet farm and wrestle the tire over the wheel... Eat your Wheaties before hand and have fun... this part sucks.

Oh yeah, the next part aint fun either. Bolting 96 bolts together with locknuts in a criss cross pattern... grab a bucket... you're gonna be here a while. (I used 3 extra long bolts to pinch the bead down to where I could use the shorter ones.

Here's a shot of them on my Jeep... They "are" painted gold to match the Jeep, but are covered in some gooey black stuff in this pic...