Garage Shelf

-

AZWOODMAN

- 1.5 Star Member

- Posts: 34

- Joined: Fri Aug 13, 2010 2:49 am

- Location: Phoenix, AZ

Garage Shelf

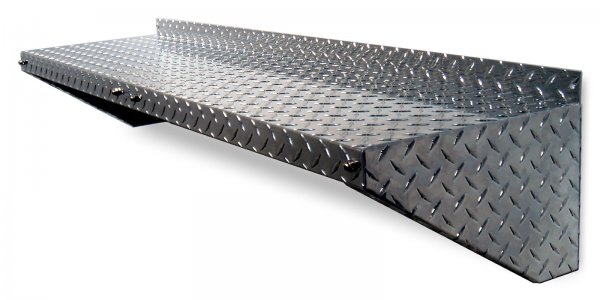

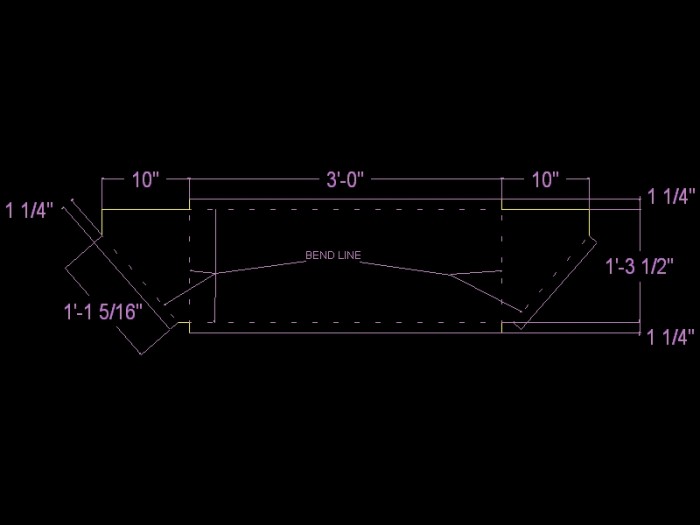

I know this isnt exactly a sheet metal forum but im sure there are some guys here with that kind of experience...Im looking to build a couple of garage shelves that are about 36inches long and 13 inches deep....Im fortunate to have the equipment to bend these out but not the smarts or experience to plan them out.....I have posted a pic of something I think would be fairly easy for a beginner....If anyone has built a few themselves or has some good ideas I would love to hear them...Thanks in advance for the ideas guys and gals...this forum has been very helpful as a metal hobbyist like myself...Thanks again

- ou812

- 2.5 Star Elite Contributing Member

- Posts: 190

- Joined: Wed Feb 25, 2009 11:18 am

- Location: Knoxville Tn.

Re: Garage Shelf

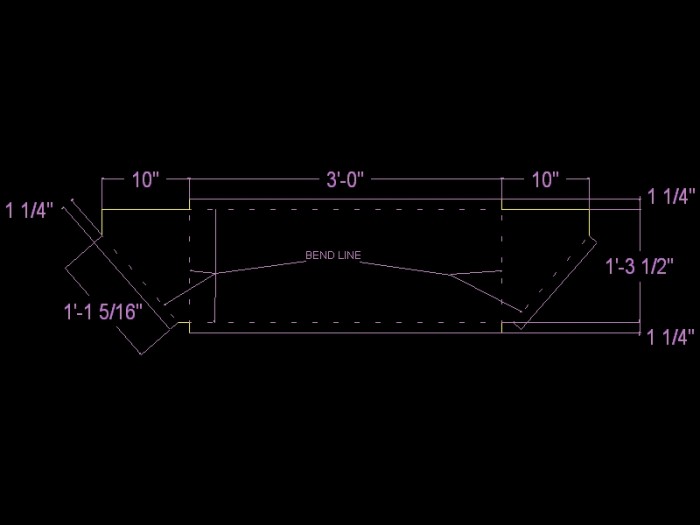

this may help

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

- Dustan

- 2.5 Star Member

- Posts: 146

- Joined: Wed Dec 23, 2009 2:04 pm

Re: Garage Shelf

awesome thanks for the file I need some of these in tha shop bad

Krazy Kutz metal designs

-

DARRYL21270

- 3 Star Member

- Posts: 491

- Joined: Fri Jun 05, 2009 7:09 am

- Location: New Jersey

- Contact:

Re: Garage Shelf

Why bother owning equipment to bend things if you don't know how to look at something and figure out how it's put together. The shelf pictured seems like an easy piece to reconstruct with a little basic knowledge. I designed and fabricated custom Gutters for commercial buildings for years using just a pad, pencil and a brake. How can you figure out how to bend it from someones diagram if you don't understand the knowledge behind it.

-

mdwalker

- 3.5 Star Elite Contributing Member

- Posts: 521

- Joined: Fri Nov 14, 2008 10:20 am

Re: Garage Shelf

DARRYL21270 wrote:Why bother owning equipment to bend things if you don't know how to look at something and figure out how it's put together. The shelf pictured seems like an easy piece to reconstruct with a little basic knowledge. I designed and fabricated custom Gutters for commercial buildings for years using just a pad, pencil and a brake. How can you figure out how to bend it from someones diagram if you don't understand the knowledge behind it.

Damn Darryl! Lighten up. The guy asked for help in about the most polite way anybody could and admitted he was weak in the design department.

-

AIRFLOWKID

- 2.5 Star Member

- Posts: 228

- Joined: Sun Sep 27, 2009 9:48 pm

Re: Garage Shelf

Darryl,

I think it's time to go get an ice tea and calm down. That's what the forum is about? Sharing and Helping!!

Tim Red Robin Creatives

I think it's time to go get an ice tea and calm down. That's what the forum is about? Sharing and Helping!!

Tim Red Robin Creatives

-

DARRYL21270

- 3 Star Member

- Posts: 491

- Joined: Fri Jun 05, 2009 7:09 am

- Location: New Jersey

- Contact:

Re: Garage Shelf

I prefer Jack Daniel's straight up  I'm just saying that some things aren't that difficult to figure out. If you can bend something then you should be able to reconstruct how it was put together. A tape measure is always helpful. Just a quick glance and you can see a back lip , the shelf and a front lip. That's 3 bends made to whatever size your looking for. If you include the sides that's 2 more and your done. Your right this is a forum but some people make a living doing this and didn't buy a plasmacam from some chintzy ad in popular mechanics.

I'm just saying that some things aren't that difficult to figure out. If you can bend something then you should be able to reconstruct how it was put together. A tape measure is always helpful. Just a quick glance and you can see a back lip , the shelf and a front lip. That's 3 bends made to whatever size your looking for. If you include the sides that's 2 more and your done. Your right this is a forum but some people make a living doing this and didn't buy a plasmacam from some chintzy ad in popular mechanics.

-

AZWOODMAN

- 1.5 Star Member

- Posts: 34

- Joined: Fri Aug 13, 2010 2:49 am

- Location: Phoenix, AZ

Re: Garage Shelf

I just dont get why individuals have to come on here just to let out their anger...Daryl this one is for you "grow up"...life is too short for this to be your biggest issue in life...If you dont wanna help someone just keep your trap shut please

-

DARRYL21270

- 3 Star Member

- Posts: 491

- Joined: Fri Jun 05, 2009 7:09 am

- Location: New Jersey

- Contact:

Re: Garage Shelf

Who's angry ???????????? I'm just not lazy and expect everyone else to do stuff for me. Some things are self explanatory without having to clog up the forum with ridiculous questions. You can clearly see from the shelf photo how it was assembled and if you know how to bend which you clearly stated you did, there should be no question about how it was put together. That's like me posting how to fold a piece of paper.

-

AZWOODMAN

- 1.5 Star Member

- Posts: 34

- Joined: Fri Aug 13, 2010 2:49 am

- Location: Phoenix, AZ

Re: Garage Shelf

Ok I am clearly not going to sit here and argue with you...your missing my point...if the post doesnt concern you and you arent willing to help....then I will give you a hint....jump to the next post and move on with life...you just posted in the picture section and said I am about to do something cool....I could have been an ass and said why dont you do something cool and then post it...instead I moved on...thats like me posting a piece of paper and saying hey look guys im going to fold this piece of paper into a really cool shape...just to use your example

-

DARRYL21270

- 3 Star Member

- Posts: 491

- Joined: Fri Jun 05, 2009 7:09 am

- Location: New Jersey

- Contact:

Re: Garage Shelf

The difference is i'm not asking how to do it  But I will file your point where I feel it's appropriate.

But I will file your point where I feel it's appropriate.

-

redneckgateart

- 2 Star Member

- Posts: 96

- Joined: Mon Aug 31, 2009 4:51 pm

- Location: Madisonville, Texas

Re: Garage Shelf

I think it's time we give this a rest.

Azwoodman asked for help and he got some. He stated up front that he had the equipment but not the experience..."Im fortunate to have the equipment to bend these out but not the smarts or experience to plan them out".

Thanks ou812 for helping him out!

Azwoodman asked for help and he got some. He stated up front that he had the equipment but not the experience..."Im fortunate to have the equipment to bend these out but not the smarts or experience to plan them out".

Thanks ou812 for helping him out!

-

DARRYL21270

- 3 Star Member

- Posts: 491

- Joined: Fri Jun 05, 2009 7:09 am

- Location: New Jersey

- Contact:

Re: Garage Shelf

It was put to rest over 7 hours ago

-

kelseywelding

- 1/2 Star Member

- Posts: 8

- Joined: Mon Feb 27, 2017 1:41 pm

Re: Garage Shelf

sweet thx

-

StanCanterbury

- 1 Star Member

- Posts: 11

- Joined: Thu Sep 20, 2012 1:38 pm

Re: Garage Shelf

Darryl you are the single reason myself and I'm sure many others do not post stuff. Do us all a favor and just keep from commenting on anything!!!

- Cz_apie

- 2.5 Star Member

- Posts: 147

- Joined: Sun Sep 04, 2016 2:10 pm

- Location: Thabazimbi South Africa

Re: Garage Shelf

Dude cool it, that post were done in 2011, why now bring it up ?StanCanterbury wrote:Darryl you are the single reason myself and I'm sure many others do not post stuff. Do us all a favor and just keep from commenting on anything!!!

Thanks

Deon

Plasmacam 4x4 DHC2 Table

Design Edge 4.36 Advanced Design

Advanced Height Control

Hypertherm PM 65

Mac Afric Cut 40 Plasma

Mac Afric Mig 195

Mac Afric Tig 200A

Thermax DC 200

Fulgor Butt Welder

13" Metal Lathe-Milling Machine

Rong Fu 25 Mill

Design Edge 4.36 Advanced Design

Advanced Height Control

Hypertherm PM 65

Mac Afric Cut 40 Plasma

Mac Afric Mig 195

Mac Afric Tig 200A

Thermax DC 200

Fulgor Butt Welder

13" Metal Lathe-Milling Machine

Rong Fu 25 Mill

-

2015cmax

- 2 Star Member

- Posts: 64

- Joined: Fri Apr 15, 2016 6:31 pm

Re: Garage Shelf

Just a thought, if you are going to use a press brake or it may apply to a box-pan type brake, you need to allow for growth of the material. So if a back panel needs to meet up at the same height as the side panel and holding the depth of the shelf, then you will need to subtract the thickness of the base material from the back or side flap. This goes back far too many years than I care to admit, but if I do remember correctly, with 1/8 material, you need a shelf depth of 10 inches and back flap of 6 inches, then your total width of material would be 15 7/8". Your brake line would be 5 7/8". This is a thumb rule. There can be several variables..