have a print need cad work done .

-

mckee ironworks

- 1 Star Member

- Posts: 15

- Joined: Thu Jun 02, 2016 8:50 am

have a print need cad work done .

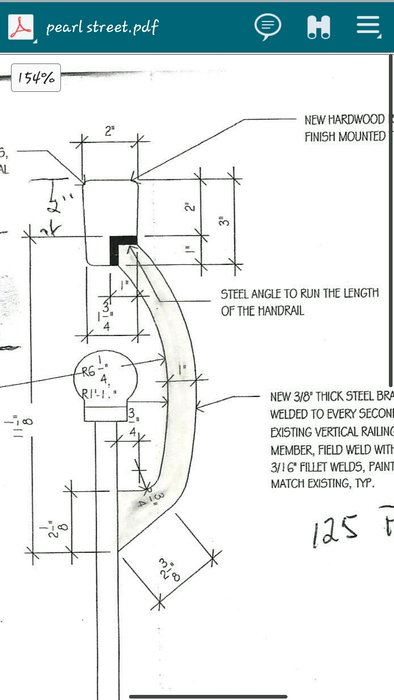

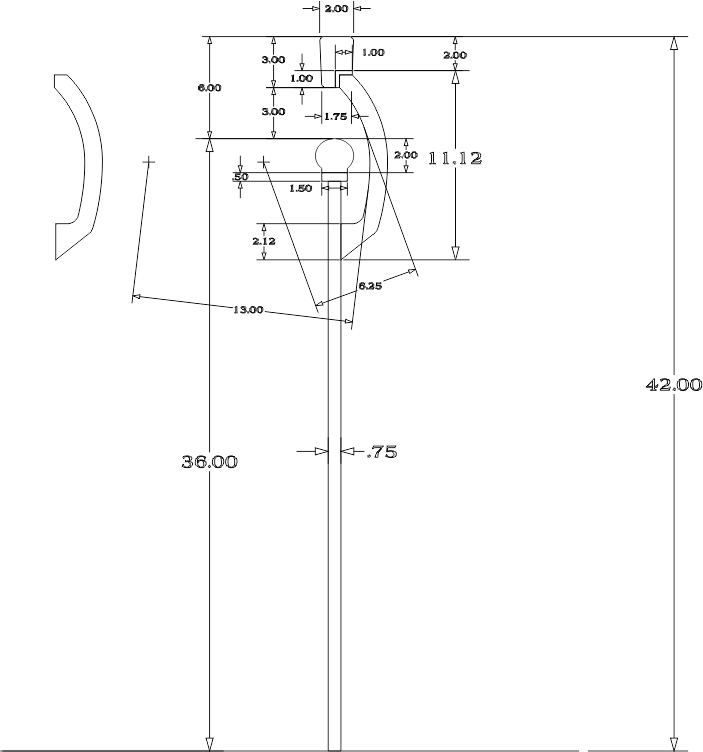

I usually just do artwork in inkscape , I have autocad 2004 and its good for very basic stuff because i just have never needed to use it . Well i am bidding a job for a handrail support it is one part times 125 pieces . I have a blueprint calling out the part I would like to get it to a dxf . Who would like to do it and how much ? Its 11 inches tall and about 3 inches wide with several rads and 90s. Any recommendations on where to go to learn this so I am not stuck in the future. Or possibly build a relationship and just hire it out .

-

mckee ironworks

- 1 Star Member

- Posts: 15

- Joined: Thu Jun 02, 2016 8:50 am

-

icmplasma85

- 3 Star Member

- Posts: 267

- Joined: Wed Nov 07, 2012 11:24 am

- Location: Virginia

Re: have a print need cad work done .

There's not enough info on that drawing as shown to draw the part accurately. I need to know where the radius' shown are measured from. There has to be a work point somewhere. PM me and we'll get it figured out. I do CAD work for a living and specialize in commercial stairs and handrails. Would definitely be interested in detailing work if you have some. I've got plenty of examples of my work. Here is a link to some older drawings I've posted on here before. Have more recent jobs I can share as well.

http://plasmaspider.com/viewtopic.php?f=3&t=18973

http://plasmaspider.com/viewtopic.php?f=3&t=18973

PlasmaCam DHC2

Hypertherm Powermax 65

Millermatic 211 MIG Welder

Hypertherm Powermax 65

Millermatic 211 MIG Welder

-

Tautog13

- 1.5 Star Member

- Posts: 46

- Joined: Fri Feb 17, 2017 4:12 pm

Re: have a print need cad work done .

I agree with icmplasma85 in that there is not enough detail in that drawing to precisely produce them.

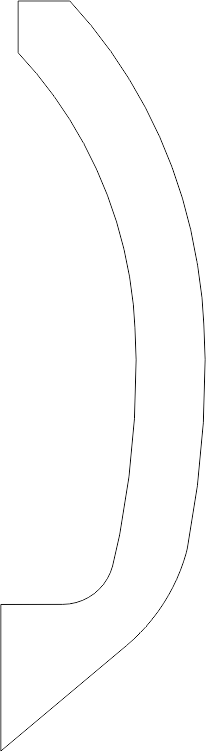

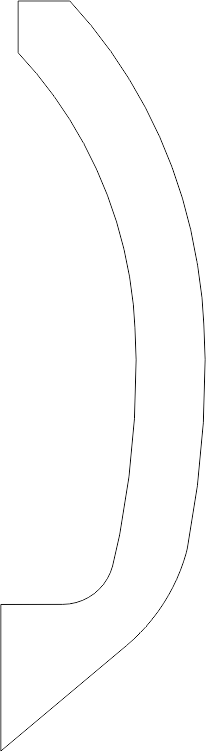

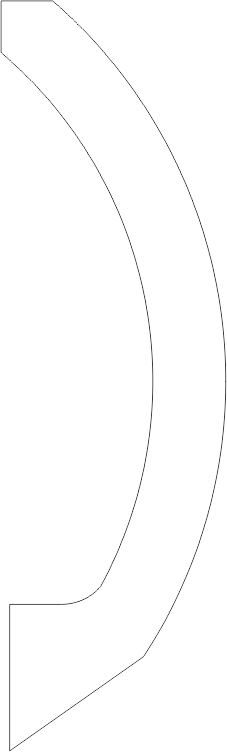

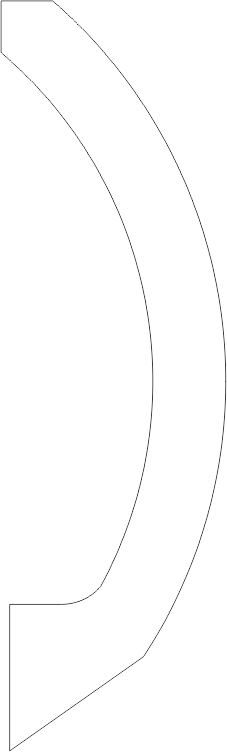

I did import/scale/trace it for my own practice & curiosity. (see attached .dxf)

I say curiosity as I am interested in what users here think of the "quality" of the .dxf as it is direct export from Trimble Sketchup (Pro)

You mention you are bidding this job, so I would recommend that you require the client provide a "clean" accurate drawing as part of your bid.

I did import/scale/trace it for my own practice & curiosity. (see attached .dxf)

I say curiosity as I am interested in what users here think of the "quality" of the .dxf as it is direct export from Trimble Sketchup (Pro)

You mention you are bidding this job, so I would recommend that you require the client provide a "clean" accurate drawing as part of your bid.

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

-

tcaudle

- 4 Star Elite Contributing Member

- Posts: 1364

- Joined: Tue Feb 28, 2012 6:47 pm

Re: have a print need cad work done .

1. A 6.5 inch radius is a 6.5" radius; It's measured from the center of the arc, You don't need to have the origin on the drawing to figure out the shape.You can find the origin point of the arc radius with a compass or in a cad program with construction lines from the end of the primary arc .

2. This is a decorative piece for a fence or railing and to be welded in place, not a piece destined for inclusion on the Mars Mission. I would think the tolerance is in the .125 in range. That is a question to the client: How accurate do they have to be as long as they are all the same?

You don't need to spend time or money on an accurate drawing to bit the job. Figure the number you can get on a sheet to get materail costs and use either a sq ft or time estimate to get a cost and add in any added costs like cleanup, paint etc And give the guy a price . If you says yes THEN you can work about developing the cut file. You may find his idea of the price and what you are willing to take are far apart and you have wasted your time.

2. This is a decorative piece for a fence or railing and to be welded in place, not a piece destined for inclusion on the Mars Mission. I would think the tolerance is in the .125 in range. That is a question to the client: How accurate do they have to be as long as they are all the same?

You don't need to spend time or money on an accurate drawing to bit the job. Figure the number you can get on a sheet to get materail costs and use either a sq ft or time estimate to get a cost and add in any added costs like cleanup, paint etc And give the guy a price . If you says yes THEN you can work about developing the cut file. You may find his idea of the price and what you are willing to take are far apart and you have wasted your time.

-

icmplasma85

- 3 Star Member

- Posts: 267

- Joined: Wed Nov 07, 2012 11:24 am

- Location: Virginia

Re: have a print need cad work done .

tcaudle wrote:1. A 6.5 inch radius is a 6.5" radius; It's measured from the center of the arc, You don't need to have the origin on the drawing to figure out the shape.You can find the origin point of the arc radius with a compass or in a cad program with construction lines from the end of the primary arc .

2. This is a decorative piece for a fence or railing and to be welded in place, not a piece destined for inclusion on the Mars Mission. I would think the tolerance is in the .125 in range. That is a question to the client: How accurate do they have to be as long as they are all the same?

You don't need to spend time or money on an accurate drawing to bit the job. Figure the number you can get on a sheet to get materail costs and use either a sq ft or time estimate to get a cost and add in any added costs like cleanup, paint etc And give the guy a price . If you says yes THEN you can work about developing the cut file. You may find his idea of the price and what you are willing to take are far apart and you have wasted your time.

I agree a radius is a radius, but how do you distinguish the R6.25" and R1' 1" as far as where they start and finish, that's what is confusing to me? Especially the 1' 1". And what I meant is they could have picked up the radius and other dimensions from a general work point found from construction line layout, not that you need a work point to know a 6" radius is a 6" radius. The detail was poorly dimensioned and in saying that I will agree that there is alot of tolerance with this part. But if you can figure out how to accurately draw that part as it's meant to be from that detail you're a better man than me. First and foremost there should be C/L dimensions through out the entire rail and there is just a bunch of out to out dimensions that some you really don't even need. It would help just to know the post size and cap rail size.

I got fed up with the "drawing it by the math" process and just traced it in designedge. Can't see it from my house.

PlasmaCam DHC2

Hypertherm Powermax 65

Millermatic 211 MIG Welder

Hypertherm Powermax 65

Millermatic 211 MIG Welder

-

mckee ironworks

- 1 Star Member

- Posts: 15

- Joined: Thu Jun 02, 2016 8:50 am

Re: have a print need cad work done .

Ok , I will blow it up some . Im sure .125 tolerance is just fine . Thank you for your help all . Brb

-

mckee ironworks

- 1 Star Member

- Posts: 15

- Joined: Thu Jun 02, 2016 8:50 am

Re: have a print need cad work done .

This all the info I have . Im sorry. First job first client.

-

icmplasma85

- 3 Star Member

- Posts: 267

- Joined: Wed Nov 07, 2012 11:24 am

- Location: Virginia

Re: have a print need cad work done .

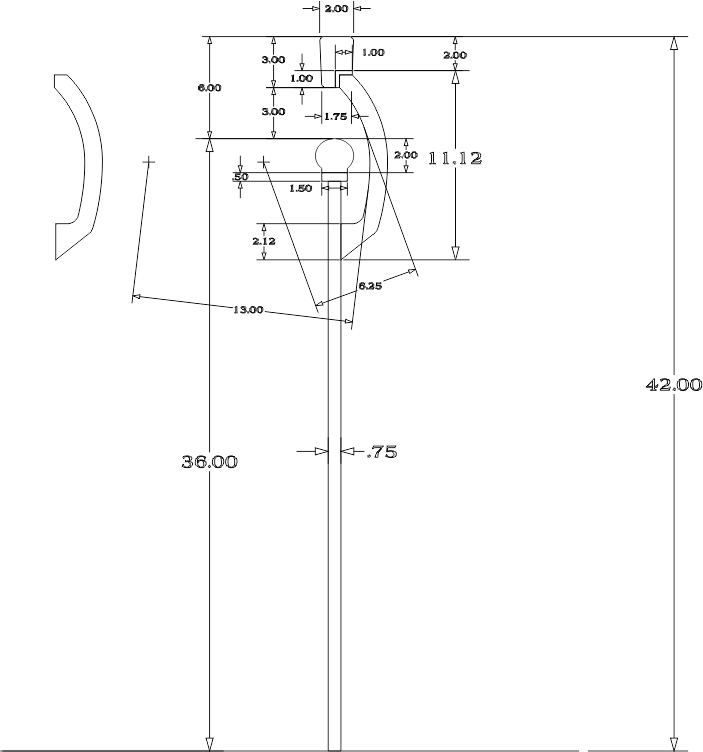

Normally I'd draw and dimension this is autocad because it's much cleaner but this is from designedge so it's a little cluttered. I actually went back and really tried to scale everything based on given dimensions and came up with this. I separated the part you need and tried to show as many dimensions as possible. This should be pretty close.

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

PlasmaCam DHC2

Hypertherm Powermax 65

Millermatic 211 MIG Welder

Hypertherm Powermax 65

Millermatic 211 MIG Welder

- Larry83301

- 5 Star Elite Contributing Member

- Posts: 2647

- Joined: Tue Oct 27, 2009 6:36 pm

- Location: Twin Falls, Idaho

Re: have a print need cad work done .

I grew it up using the centerline of the other support and the piece of angle iron at the top. this is what I came up with. It's an Acad 14 file so any dims you need should just pop up if you select the item in analyze. If you need it dimensioned just ask.

Larry

Larry

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

-

mckee ironworks

- 1 Star Member

- Posts: 15

- Joined: Thu Jun 02, 2016 8:50 am

Re: have a print need cad work done .

I am very green to this . I was unaware that the request for quote i was given was not a job they had , but a job they were bidding . So I get the bid in and was told they will contact me if they are awarded the job . I deeply apologize for this posting . I was under the impression that this was a job they had and needed the parts . I was ok figuring out a time and cost for the bid but I would have to get some help on the cad end and put it on here basically looking for a price . So now I sit and wait . I appreciate all of your input and help. In the future I will work in my own cad skills and hopefully I can develop some networking on here. I never would expect anyone to work for free . I am a firm believer in give a man a fish ya feed him for a day but if you teach that man to fish you feed him for a life time . Thank you all again for the speedy reply and willingness to help me out of a jam .

- _Ogre

- 3.5 Star Member

- Posts: 529

- Joined: Sun Sep 15, 2013 4:26 pm

- Location: Motown

Re: have a print need cad work done .

you have a pdf of the drawing. chances are you could have asked for the drawing for import into autocad for conversion into a dxf. as for the rfq, that is typical of the whole industry. if it was a less than 100 small parts you could have given the job away for the cost of materials and consumables to get in with the contractor and not been out of pocket for much other than time. time for education

that's a very simple 2D bracket to draw in autocad and i'd recommend that if you're going to bid on future work that you learn to use autocad. all the dimensions are there: overall length, radius's and basic flange widths. the only unknowns i see are the thickness of the angle iron attached to the handrail and the location of the 6.25 radius. it could be scaled off the drawing and be close enough for a handrail job.

the basic drawing is a couple straight lines and a couple of circles trimmed to fit. one radius is dimensioned but the location of the 6.25 radius is hanging in the air. an easy way to do this is to import the picture into autocad and scale it to full size. the draw to the dimensions specified and see how it fits. very few commands need to draw that bracket and most can be typed in faster than finding the menu item. L for line, C for circle, TRIM to trim the circles and extended lines. the hardest part is import and scale of the drawing.

i can teach you to fish and am a firm believer in learning the process. i do all of my drawing in autocad as i do mostly parts, not art. no guru by a long stretch but i get by. if you need help ask here or pm me on autocad questions. i'm not here as often as you may need but we can work thru email or text

that's a very simple 2D bracket to draw in autocad and i'd recommend that if you're going to bid on future work that you learn to use autocad. all the dimensions are there: overall length, radius's and basic flange widths. the only unknowns i see are the thickness of the angle iron attached to the handrail and the location of the 6.25 radius. it could be scaled off the drawing and be close enough for a handrail job.

the basic drawing is a couple straight lines and a couple of circles trimmed to fit. one radius is dimensioned but the location of the 6.25 radius is hanging in the air. an easy way to do this is to import the picture into autocad and scale it to full size. the draw to the dimensions specified and see how it fits. very few commands need to draw that bracket and most can be typed in faster than finding the menu item. L for line, C for circle, TRIM to trim the circles and extended lines. the hardest part is import and scale of the drawing.

i can teach you to fish and am a firm believer in learning the process. i do all of my drawing in autocad as i do mostly parts, not art. no guru by a long stretch but i get by. if you need help ask here or pm me on autocad questions. i'm not here as often as you may need but we can work thru email or text

bulltear 4x8 cnc plasma table, candcnc bladerunner w/dthc, hypertherm powermax 65, sheetcam, mach3

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley how cool!

how cool!

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley

-

tcaudle

- 4 Star Elite Contributing Member

- Posts: 1364

- Joined: Tue Feb 28, 2012 6:47 pm

Re: have a print need cad work done .

Well. you are not as Green as you were when you did the first post! Welcome to the world of job shop work. You just saved them a lot of work figuring up individual parts and they may never get the job or you may never hear from them if they do get the job. You will never make much doing contract cutting of simple parts. Either you will be too high or you won't make much more than beer money after expenses.

Having drawing skills (especially how to use the tool in you drawing program to create and /or edit existing art ) are valuable. You make money on a job based on how quickly you can do a proof of concept and get it off the table and finished. Learning how to hand trace is also very important. I found I was never able to charge a fee for the artwork I had a rule that we did the first proof of concept and the customer could change it ONE TIME. After that it cost. It ts amazing how quickly they can make a decision when the fees start to roll. SInce virtually everything we did was custom in some form or another , we had them sign off on the drawing , and do a deposit. I only had one customer that did not come and pick up their work after a deposit. I had several BEFORE I started that left me with custom cutouts. All I could do was hang them on the "sample" wall. Telling a customer (other than a commercial job) that you will get back to them with a price will lose you 50% of jobs. You have to be able to give them a ballpark (range) based on the size and finish. deliver the proof quickly and keep them engaged in the process. It's kinda like where you see on the website "Call for Quote" . Translated that means (to me) : Its expensive and somebody will need to talk to you and sell you on why.

Having drawing skills (especially how to use the tool in you drawing program to create and /or edit existing art ) are valuable. You make money on a job based on how quickly you can do a proof of concept and get it off the table and finished. Learning how to hand trace is also very important. I found I was never able to charge a fee for the artwork I had a rule that we did the first proof of concept and the customer could change it ONE TIME. After that it cost. It ts amazing how quickly they can make a decision when the fees start to roll. SInce virtually everything we did was custom in some form or another , we had them sign off on the drawing , and do a deposit. I only had one customer that did not come and pick up their work after a deposit. I had several BEFORE I started that left me with custom cutouts. All I could do was hang them on the "sample" wall. Telling a customer (other than a commercial job) that you will get back to them with a price will lose you 50% of jobs. You have to be able to give them a ballpark (range) based on the size and finish. deliver the proof quickly and keep them engaged in the process. It's kinda like where you see on the website "Call for Quote" . Translated that means (to me) : Its expensive and somebody will need to talk to you and sell you on why.