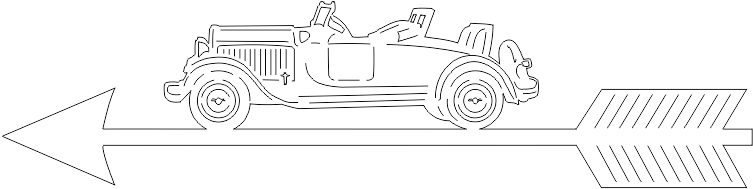

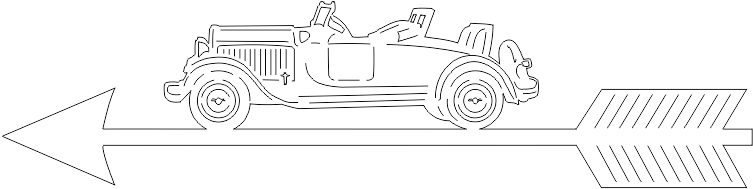

Wind Vane

- d2day

- 2.5 Star Member

- Posts: 114

- Joined: Wed Sep 17, 2014 7:59 pm

Wind Vane

My first attempt to share so be gentle until I learn how to do it properly...LOL This is a project that I did for a friend and found that a lot of people liked it so hopefully some of you can use it. I have some other versions I will post later if there is some interest. The dxf file was saved as a version 13 autocad file. I use .svg for sheetcam myself. I did not attach the e/w/n/s/ part of the file because it is pretty simple to make, but if someone needs it I will post it later. My thanks for all the files and help I have gotten here...

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

Mach 3

SheetCam

Corel x5 / Version 12/ Version 7

ArtCam 7.0

CNC Router

ULS Laser

4x4 Plasma Table/Hand Built

HyperTherm PowerMax 45

Cut Shop Software

LCTHC

SheetCam

Corel x5 / Version 12/ Version 7

ArtCam 7.0

CNC Router

ULS Laser

4x4 Plasma Table/Hand Built

HyperTherm PowerMax 45

Cut Shop Software

LCTHC

-

eggauto

- 2.5 Star Elite Contributing Member

- Posts: 178

- Joined: Sun Jul 18, 2010 7:59 pm

Re: Wind Vane

Congrats you got it. It looks great. Thank you.

- Buzzard Gut

- 3 Star Member

- Posts: 364

- Joined: Mon Jun 27, 2011 2:07 pm

- Location: Coos Bay Oregon

- HammerDownJustin

- 3.5 Star Member

- Posts: 613

- Joined: Mon Mar 04, 2013 10:41 pm

- Location: Paradise,Tx

Re: Wind Vane

Pretty nice and thank you. I have been wanting to make one. Just not sure exactly how to offset the weight. I want it to actually work also.

Home built 5x10 table CandCNC electronics

Miller 251 Mig

And lots of other cool stuff...

Miller 251 Mig

And lots of other cool stuff...

- Larry83301

- 5 Star Elite Contributing Member

- Posts: 2646

- Joined: Tue Oct 27, 2009 6:36 pm

- Location: Twin Falls, Idaho

Re: Wind Vane

Looks great, love the car!

Larry

Larry

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 7784

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Wind Vane

Thanks for posting could you post it in SVC???

Sean P does wind vanes and should be able to answer the positioning question.

Sean P does wind vanes and should be able to answer the positioning question.

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

- d2day

- 2.5 Star Member

- Posts: 114

- Joined: Wed Sep 17, 2014 7:59 pm

Re: Wind Vane

Here is the svg file.

The wind vane is fully functional as shown. I can add details of how it was built if needed.

The wind vane is fully functional as shown. I can add details of how it was built if needed.

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

Mach 3

SheetCam

Corel x5 / Version 12/ Version 7

ArtCam 7.0

CNC Router

ULS Laser

4x4 Plasma Table/Hand Built

HyperTherm PowerMax 45

Cut Shop Software

LCTHC

SheetCam

Corel x5 / Version 12/ Version 7

ArtCam 7.0

CNC Router

ULS Laser

4x4 Plasma Table/Hand Built

HyperTherm PowerMax 45

Cut Shop Software

LCTHC

- d2day

- 2.5 Star Member

- Posts: 114

- Joined: Wed Sep 17, 2014 7:59 pm

Re: Wind Vane

My thanks to eggauto for leading me in the right direction so I could start sharing....

Mach 3

SheetCam

Corel x5 / Version 12/ Version 7

ArtCam 7.0

CNC Router

ULS Laser

4x4 Plasma Table/Hand Built

HyperTherm PowerMax 45

Cut Shop Software

LCTHC

SheetCam

Corel x5 / Version 12/ Version 7

ArtCam 7.0

CNC Router

ULS Laser

4x4 Plasma Table/Hand Built

HyperTherm PowerMax 45

Cut Shop Software

LCTHC

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 7784

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Wind Vane

Thanks for the SVG that opened fine but the DFX looked like this in SheetCam.

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

RGR

- 2.5 Star Member

- Posts: 107

- Joined: Wed Dec 11, 2013 3:21 am

Re: Wind Vane

Id be interested to see how its made. Ive been wanting to make one,but didnt know where to start. Thanks!!d2day wrote:Here is the svg file.

The wind vane is fully functional as shown. I can add details of how it was built if needed.

- ben de lappe

- 4 Star Elite Contributing Member

- Posts: 1226

- Joined: Mon Aug 03, 2009 9:37 am

- Location: North Mississippi

Re: Wind Vane

Out of curiosity Tom, does SheetCam have an option to close paths upon importation? That's pretty much what I get in TM CAD if this setting is applied.acourtjester wrote:Thanks for the SVG that opened fine but the DFX looked like this in SheetCam.

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 7784

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Wind Vane

I cannot answer the question, it will tell you if there are overlapping lines.

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

- steel 35

- 3.5 Star Member

- Posts: 634

- Joined: Sun Jan 11, 2015 11:12 am

- Location: N of Cali.

Re: Wind Vane

acourtjester wrote:Thanks for the SVG that opened fine but the DFX looked like this in SheetCam.

Mine was much nicer the that! Just two lines that may try to cut twice.

Very nice car thank you.

PPL HDG 4X8

Hyp 65 duramax's

C&CNC 620-5 Ethernet

Inkscape, Solid Edge, Sheetcam, Autocad 2K

Corel X7 Student NO DXF!

EasyScriber

Hyp 65 duramax's

C&CNC 620-5 Ethernet

Inkscape, Solid Edge, Sheetcam, Autocad 2K

Corel X7 Student NO DXF!

EasyScriber

-

muzza

- 4 Star Member

- Posts: 1472

- Joined: Wed Feb 04, 2009 5:35 pm

Re: Wind Vane

acourtjester wrote:Thanks for the SVG that opened fine but the DFX looked like this in SheetCam.

Tom, if it comes into Sheetcam looking like that it is generally because the scaling is wrong, the centreline marks also tell us this. I work in metric and if I bring in an inch file that is exactly what it looks like.

Murray

PS, there are a few threads here with a lot of info on making weather or wind vanes easily found using the search function for those wanting more info on making them.

- d2day

- 2.5 Star Member

- Posts: 114

- Joined: Wed Sep 17, 2014 7:59 pm

Re: Wind Vane

After looking at the "mess" the dxf file made when opened in sheetcam I was very glad someone was able to explain what happened. I personally had no clue.

I am relatively new to plasma cutting and sheetcam as I only have about two years experience. I have several years with cnc routing and the problems associated with that and using a laser cutter. The laser is pretty straight forward, the router not as easy. Plasma has been more of a challenge as I started with a machine I built myself. The learning curve has been slow especially since I am not a spring chicken anymore.

Sharing files is apparently another hurdle to cross, bear with me I am willing to share some of my work as I have been creating files for the better part of 14 years, and want to give back.

Thank you all again for your help and advice.

I am relatively new to plasma cutting and sheetcam as I only have about two years experience. I have several years with cnc routing and the problems associated with that and using a laser cutter. The laser is pretty straight forward, the router not as easy. Plasma has been more of a challenge as I started with a machine I built myself. The learning curve has been slow especially since I am not a spring chicken anymore.

Sharing files is apparently another hurdle to cross, bear with me I am willing to share some of my work as I have been creating files for the better part of 14 years, and want to give back.

Thank you all again for your help and advice.

Mach 3

SheetCam

Corel x5 / Version 12/ Version 7

ArtCam 7.0

CNC Router

ULS Laser

4x4 Plasma Table/Hand Built

HyperTherm PowerMax 45

Cut Shop Software

LCTHC

SheetCam

Corel x5 / Version 12/ Version 7

ArtCam 7.0

CNC Router

ULS Laser

4x4 Plasma Table/Hand Built

HyperTherm PowerMax 45

Cut Shop Software

LCTHC

- d2day

- 2.5 Star Member

- Posts: 114

- Joined: Wed Sep 17, 2014 7:59 pm

Re: Wind Vane

I have to build another wind vane in a few days for another customer, I will take some photos of the steps along the way and post the results for those of you that may be interested.

Mach 3

SheetCam

Corel x5 / Version 12/ Version 7

ArtCam 7.0

CNC Router

ULS Laser

4x4 Plasma Table/Hand Built

HyperTherm PowerMax 45

Cut Shop Software

LCTHC

SheetCam

Corel x5 / Version 12/ Version 7

ArtCam 7.0

CNC Router

ULS Laser

4x4 Plasma Table/Hand Built

HyperTherm PowerMax 45

Cut Shop Software

LCTHC

- Zippo

- 4.5 Star Elite Contributing Member

- Posts: 1709

- Joined: Fri Mar 04, 2011 12:49 pm

- Location: Minnesota Based

Re: Wind Vane

Thanks for posting.

-

shinertx

- 3 Star Elite Contributing Member

- Posts: 287

- Joined: Wed Aug 27, 2014 12:03 pm

- Location: Shiner

Re: Wind Vane

Very Nice.

Samson 5x10

Designedge software

Hypertherm Powermax 65

Hypertherm powermax 380

Thermodynamics cut master 85

Jet 4' box & pan break

Eastwood Powder coating guns.

Designedge software

Hypertherm Powermax 65

Hypertherm powermax 380

Thermodynamics cut master 85

Jet 4' box & pan break

Eastwood Powder coating guns.

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 7784

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Wind Vane

Thanks Muzza that may explain things, There have been other problems when crossing software lines (different CAD programs) creating one and reading in another.

d2day

Your not the only old rooster here

have fun

Tom

d2day

Your not the only old rooster here

have fun

Tom

Last edited by acourtjester on Mon Mar 21, 2016 11:41 am, edited 1 time in total.

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

motoguy

- 4 Star Elite Contributing Member

- Posts: 1184

- Joined: Tue Aug 25, 2015 12:05 pm

- Location: Central MO, USA

Re: Wind Vane

That would be awesome. Thank you!d2day wrote:I have to build another wind vane in a few days for another customer, I will take some photos of the steps along the way and post the results for those of you that may be interested.

Bulltear 6x12 w/ Proton Z axis & watertable

CommandCNC/Linux w/ Ohmic & HyT options

Hypertherm Powermax 85 w/ machine torch

Solidworks, Coreldraw X7, Inkscape, Sheetcam

CommandCNC/Linux w/ Ohmic & HyT options

Hypertherm Powermax 85 w/ machine torch

Solidworks, Coreldraw X7, Inkscape, Sheetcam

- SeanP

- 4 Star Member

- Posts: 950

- Joined: Thu Aug 01, 2013 11:50 am

- Location: Co Kerry, Ireland

Re: Wind Vane

I've done a few , but I'm no expert!acourtjester wrote:Thanks for posting could you post it in SVC???

Sean P does wind vanes and should be able to answer the positioning question.

I did read they should be balanced on the pivot but have a larger surface area at the rear, I went to great lengths to get that right on some I did.

I find doing that they tentd to sway one way then the other a lot, works great in a light breeze and maybe less wear on the pivot, but then again it's none stop moving one way then the other so who knows.

Now I would rather have a bit of weight towards the rear and a larger area further back as well.

Nice car design there, loaded fine here thanks.

I think if I was using that as it is I would go for mounting the pivot right under the front edge of the door.

Powermax XP45

Home built table, Candcnc DTHC 2, Dragoncut 620-4

R-Tech 210 Tig, Jasic 250 mig

Sheetcam, Scanything, Coreldraw

Table build gallery

Home built table, Candcnc DTHC 2, Dragoncut 620-4

R-Tech 210 Tig, Jasic 250 mig

Sheetcam, Scanything, Coreldraw

Table build gallery

-

Bill Reibelt

- 1 Star Member

- Posts: 21

- Joined: Wed Jun 24, 2015 9:23 pm

Re: Wind Vane

Thanks for posting, great looking piece and converts to Corell well, no issues. Bill

- d2day

- 2.5 Star Member

- Posts: 114

- Joined: Wed Sep 17, 2014 7:59 pm

Re: Wind Vane

Support and pivot ...A member asked for an explanation of how the support and pivot work so here is a basic drawing, any sizes may be changed or modified to suit any materials you may have on hand. Moving the balance point and extending the length of the arrow at the feather end may help in the overall working of the wind vane. Of course grease should be added to help with the movement and drain holes placed in the pipe so moisture will drain..

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

Mach 3

SheetCam

Corel x5 / Version 12/ Version 7

ArtCam 7.0

CNC Router

ULS Laser

4x4 Plasma Table/Hand Built

HyperTherm PowerMax 45

Cut Shop Software

LCTHC

SheetCam

Corel x5 / Version 12/ Version 7

ArtCam 7.0

CNC Router

ULS Laser

4x4 Plasma Table/Hand Built

HyperTherm PowerMax 45

Cut Shop Software

LCTHC

-

Rex

- 3 Star Elite Contributing Member

- Posts: 316

- Joined: Sat Oct 08, 2016 12:26 pm

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 7784

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Wind Vane

d2day on the vane I built I flipped the mount so the blue tube in your drawing is attached to the vane. Then there is much less a chance for any moisture getting in.

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT