My new air compressor from Lowes got delayed another week so I have had time to build my air system getting ready for it's arrival.

I read a lot about people building their own air dryers on a few sites and went out searching for something to build.

For some reason I could not find a plumbing place that had any thick walled pipe to make my origional planned pipe with 2 caps on it.... PVC was out because it wont take more than 130 PSI and safety was an issue because exploding PVC bits with desicant dosen't sound like something I want getting into my beer when it explodes.....

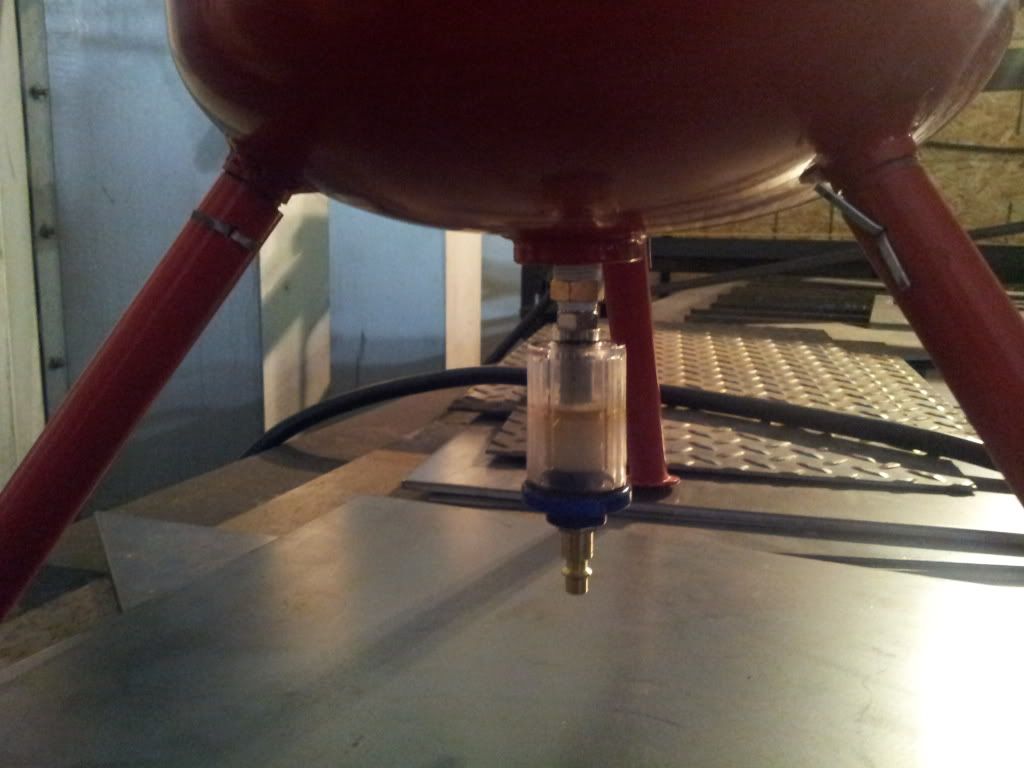

So, I picked up a 20lb sandblaster from Hazard Fraught for 45.00$, I put an inline filter on the bottom to trap any of the dessicant beads inside the tank and the window on the bottom will also let me know when I need to recharge the dessicant when moisture shows in the glass.

The pressure tank has a fitting on the top that I bought at Lowes that is a blow off valve that will not let the vessel get over 115 PSI, the tank is rated for more but not much more.... and that thing going bang would be a terrible mess.

In the pics you can see that just downstream from the dryer (6' of hose) there is a pressure regulator and element filter that should clean up any residual moisture or contaminants before my beautiful Hypertherm 45.

I found a ton of places selling dessicant in lots of forms, Gel, Beads, Crystals and even a few sites that recommended silica sand and rock salt for moisture removal..... I decided that beads would be the best even though they are the most expensive out of the choices. I figure when i need to recharge them I can easily pour them out from the pressure vessel and not have some sort of solid moisture ridden salt block that will not ever come out of the tank.

The plan is to position this dryer behind the table, hence behind the 3/16" steel shield under the table, just in case it goes pop at some point in time.

These beads are about 25 bucks a gallon and I figure I will need about 4 gallons to fill it up.

All in all, it should work out pretty good....now im just waiting for the compressor and the beads.

Enjoy